+49 [0] 36848 4790 - 0

info@pcg-gmbh.de

Home

Knowledge transfer and training for specific techniques for hard metal production processes Material Analysis for microstructure evaluation, physical and chemical levels, particularly for hard metal Specifications of materials selection for solid carbide and carbide composite - tools, including life improvements Optimization and redesign of tool parts and complete tools made of carbide and carbide steel composites As part of the machining (turning, drilling and milling) creation of tool-specific work plans and corresponding optimized tool use plans Another engineering - service for identification and reduction of potential costs

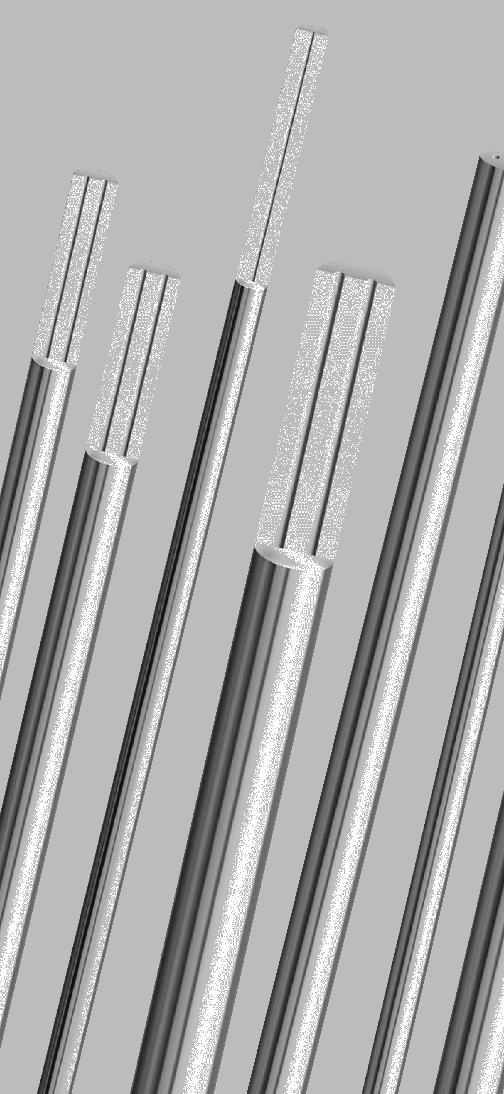

Shortest lead times through large amount of standard dimension tungsten rods permanently stocked in our warehouse in Schwallungen, central Germany

We offer:

grinding

coating

eroding

soldering

polishing

labeling

Preparation of specimen

Magnetic saturation (4πσ) and coercive force (Hc)

Density

Hardness (HV30)

Palmquist-Test at polished cut

Assessment of microstructural section

EDX analysis (energy dispersive X-ray spectroscopy)

SEM analysis (scanning electron microscope)

Copyright ©2024 PPS Medienstudio All Rights Reserved